Skin wound repair is a common clinical problem, and in an article recently published in the journal ACS Applied Materials and Interfaces, an asymmetric composite dressing was fabricated by preparing an asymmetric surface and altering the wettability of the sponge on both sides by electrospinning. It is prepared by freeze-drying a sponge composed of collagen and quaternized chitosan (Col/QCS), in which the inner layer is made of poly(ε-caprolactone) (PCL)/gelatin (Gel) nanofibers imparted with hydrophilicity Sexual modification. On the other hand, by modifying the outer layer of the sponge with micro-nanostructures, PCL/polystyrene microspheres imparted hydrophobicity on each side and were used in severe burn wound healing.

The morphology and properties of fabricated asymmetric composite dressings synergistically promote antibacterial activity in severe burn wound healing by managing cellular behavior. Experimental results obtained from in vitro studies suggest that the inner layer of the nanofiber-aligned sponge promotes all stages from cell adhesion to proliferation. The outer layer exhibits resistance to bacterial adhesion and exhibits good mechanical properties.

Another hand, in vivo results, showed that the prepared composite dressing could reduce the inflammatory response, accelerate angiogenesis, prevent infection and epithelial regeneration, and accelerate the healing of severe burns. Therefore, the proposed asymmetric composite dressing is expected to be a potential candidate for severe burn wound healing.

Effective dressing for severe burn wound healing

According to tissue engineering research, the composition, morphology and surface structure of biomaterials can affect cell behavior and fate. Thus, the dramatic effect on stem cells directs their differentiation, promoting nerve regeneration and bone regeneration.

Although various dressings based on hydrogels, sponges, and bioactive agent-loaded membranes are used for wound healing of severe burns, the efficiency of these dressings is limited to their dressing composition, ignoring the effects of structure and topography. Different novel wettable dressings were prepared by bioprinting, electrospinning, and phase switching (dry/wet).

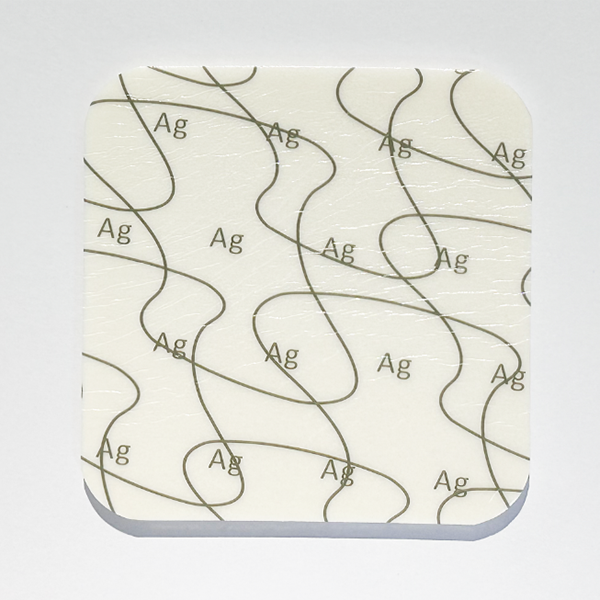

A composite dressing that mimics natural skin with wettability and asymmetric structure has been developed to promote wound healing in severe burns. The outer layer has a layered micro-nano structure, inspired by the lotus leaf effect, which prevents contamination caused by bacterial adhesion.

The researchers characterized the morphological and wettability characteristics of the material. The nanofibers exhibited smooth, continuous, and bead-free uniform morphology, while the orientation of the nanofibers did not affect the diameter of the nanofibers. The biomimetic surface with similar hierarchical micro-nanostructures on the other side exhibited similar superhydrophobic properties. The natural superhydrophobic surface structure in lotus leaf has inspired the development of various micro- and nanostructures. These micro-nanostructures mimic natural superhydrophobic surfaces with enhanced surface roughness, which reduces contact with water and thus improves the material's hydrophobicity. Therefore, the preparation of asymmetric dressings with an antibacterial outer layer based on the biomimetic hydrophobic principle is helpful in achieving effective dressings for severe burn wound healing.

Furthermore, the inner layer aligned with the nanofibers mimics the structure of the dermis, thereby enhancing biological processes ranging from cell adhesion to macrophage polarization. In addition, the inner layer-loaded cur showed antioxidant and antibacterial properties that synergized with the morphological structure to reduce the inflammatory response and accelerate wound healing in severe burns.

refer to

He, C., Yu, B., Lv, Y., Huang, Y., Guo, J., Li, L., Chen, M, et al. (2022). Electrospun biomimetic asymmetric composite dressings with aligned nanofibers and micropatterned structures for severe burn healing. ACS Applied Materials and Interfaces. https://doi.org/10.1021/acsami.2c04323

English

English عربى

عربى Español

Español русский

русский 中文简体

中文简体

.jpg.png?imageView2/2/format/jp2)

.jpg.png?imageView2/2/format/jp2)

.jpg.png?imageView2/2/format/jp2)